Preparation is important for successful powder coating. All Filth, oil, and debris get cleaned from the part in query since these could hinder powder adhesion in later steps. This preparing action could include a number of methods in by itself, with regards to the substance in query along with the initial point out on the section.

Squander Management: Employ successful waste management techniques for overspray Restoration and recycling of extra/residual powder.

Coming up with another era of sections and technological answers is a posh and intricate method that needs a deep idea of both of those variety and performance. Innovators and designers need to deal with building items that not merely meet certain functional specifications, but will also enchantment aesthetically to buyers.

The phosphate and chromate alternatives utilized aren’t eco-friendly. Due to this, many coating services have changed them with titanium zirconium silanes, which offer comparable corrosion resistance and powder adhesion properties.

While thick levels of powder coating treatment effortlessly and so are easily applied, slim levels is often difficult. Considering that the powder’s particle sizing is very substantial, slender layers normally show the orange peel influence.

Speed up your Make Along with the swiftest online tailor made laser slicing, digital prototyping & manufacturing company for startups & enterprises.

Masking Methods for Exact Apps: Occasionally, sections require specific parts to remain uncoated. This is where masking goods like masking dots appear into Participate in. They're accessible in various designs and forms, typically built of paper or plastic film coated having a strain-sensitive adhesive.

Pre-cure System: Ensure extensive cleansing and area preparing right before powder coating. Good pretreatment boosts adhesion and helps prevent defects.

Powder particles pass through the ionized electrostatic area, become charged, and therefore are deposited about the electrically grounded floor of the element.

UV curable powder coating is comparable to thermoplastic coating, apart from it cures beneath UV light in lieu of at large temperatures. The benefits Allow me to share legion. Due to the fact this process doesn’t call for significant temperatures, warmth-delicate products for example Wooden and natural and organic fibers may also be powder coated.

This is often the initial step in the method. If you don't have usage of a sandblaster, You can even make use of a wire wheel, bench-grinder, and even sandpaper. Just as long as you get the fabric down to bare metal. The next move would be to strip the metal of any remaining grime or gunk. You may reach this by soaking the merchandise in acetone (If your item is sufficiently small) or by wiping it using an acetone-soaked rag.

Total, powder coating is a superb choice for metal elements, but its application to non-metal supplies should be thoroughly regarded as and brought with warning.

wikiHow marks an posting as reader-authorised after it gets adequate optimistic feedback. This article acquired seventeen testimonials and a hundred% of readers who voted identified it valuable, earning it our reader-permitted position.

UV powder las vegas metal finishing coating purposes use UV LED curing units, which are extra environmentally friendly than regular curing ovens. Their high Vitality performance, paired While using the reduced-temperature requirements and rapidly curing situations of UV-cured powders, minimize manufacturing expenses significantly compared to thermoplastic and thermoset apps.

Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Marcus Jordan Then & Now!

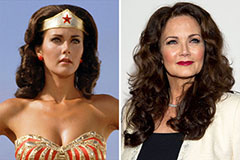

Marcus Jordan Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!